Related Posts

White Aluminum Oxide Sandblast Abrasive

Mohs Hardness: 8-9 Bulk Density: 125 lbs cuft White fused aluminum oxide is a very high purity oxide Used when contamination is an issue to be considered Very hard /…

Soda Blast Sandblast Abrasive

Mohs Hardness: 2.5 Bulk Density: 60 lbs cuft Sodium Bicarbonate Abrasive Non-Destructive Blast Abrasive Soda can be used in Mobile applications and with Cabinets and Blast Rooms Good restoration and…

Why a Complete Breathing Air System Matters for Blasting Safety

Abrasive blasting environments demand a higher level of operator protection, and the breathing air system plays a central role in that safety equation. From airline filtration and climate control to…

10X Engineered Materials

Mohs Hardness: 7-8 Bulk Density: 90-105 lbs cuft Made of Spherical, Angular, Sub-Angular and Oval Shaped Abrasives Significantly Delays Flash Rust Good replacement of Garnet - Cuts Faster (at all…

Iron Grit Abrasive

Mohs Hardness: 7 Bulk Density: 160 lbs cuft Hard, Heavy good etching abrasive Breaks down in small angular pieces Wear on nozzles and hoses Angular Shaped / Dark Grey or…

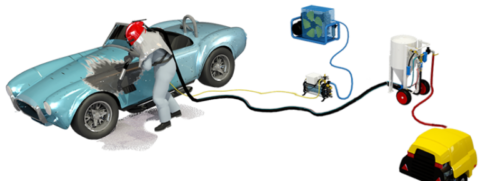

Abrasive Blast System Sizing Guide

Abrasive Blast System Sizing Guide With Blue Dog Blasting on your team, you have access to the sandblasting expertise that only comes with decades of sandblasting experience. The table below