Related Posts

Long Venturi Nozzle

The long venturi nozzle offers a 40% increase in production over a straight bore nozzle. Made with a protective polyurethane jacket, these nozzles are obviously built for physically demanding operations.

Abrasive Embedment

The Debate on Abrasive Embedment in Sandblasting There’s a lot of disagreement in the sandblasting industry about abrasive embedment. This includes business owners, industry professionals, and especially companies that make

Abrasive Blast System Sizing Guide

Abrasive Blast System Sizing Guide With Blue Dog Blasting on your team, you have access to the sandblasting expertise that only comes with decades of sandblasting experience. The table below

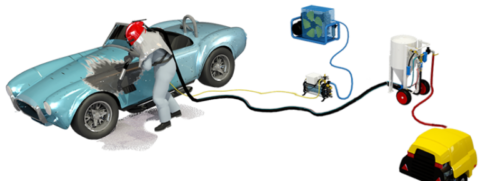

Upgrading Your Blast Process as Your Powder Coating Business Grows

At Blue Dog Blasting, we typically see powder coaters upgrade their blasting process in three common stages: Good, Better, and Best. There are many ways to improve a blast operation,…

Types of Metering Valves

Return Types of Metering Valves Choosing the right metering valve can be tricky. Even just calling it a metering valve has it’s issues. Some people call them grit valves, or

Garnet Abrasive

Mohs Hardness: 6.5-7 Bulk Density: 140 lbs cuft Used in Sandblast and Waterjet Relatively Hard Mined Mineral Heavy Abrasive Requires Higher Pressures to be effective Less than 10% Mined in…