Nozzle Material Guide

All sandblasting nozzles have limited life spans and choosing the cheapest option may not always be the best option. That’s why we put together the Nozzle Material Guide!

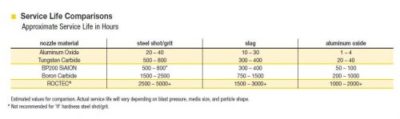

But what nozzle material delivers the best bang for your buck? This abrasive blasting nozzle material guide should help answer that question.