Related Posts

How Much Air Do You Need For Your Abrasive Blast Process?

Abrasive Blast Process Air Consumption FAQs? When it comes to air consumption for your abrasive blast process, how much is enough? How much compressed air do you really need for

Panblast Abrasive Blasting Hoses

Panblast Abrasive Blasting Hoses Panblast hoses from Blue Dog Blasting provide strong and durable abrasive sandblasting hoses with maximum air pressure and optimum lifespans. Don’t settle for an old thinning

Garnet Abrasive

Mohs Hardness: 6.5-7 Bulk Density: 140 lbs cuft Used in Sandblast and Waterjet Relatively Hard Mined Mineral Heavy Abrasive Requires Higher Pressures to be effective Less than 10% Mined in…

Silcion Carbide

Mohs Hardness: 9 Bulk Density: 95 lbs cuft Hardest of Non-Metallic Abrasives Fast Cutting of Coatings Silicon carbide is a ceramic material with an excellent hardness Hard brittle grains shatter…

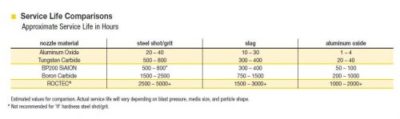

Nozzle Material Guide

Return Nozzle Material Guide All sandblasting nozzles have limited life spans and choosing the cheapest option may not always be the best option. That’s why we put together the Nozzle

Sure Cut Sandblast Abrasives (Velocity & Edge)

Consumption rate reductions of up to 30-percent vs Coal Slag Faster cutting rates producing up to 50-percent less time on the job vs Coal Slag Reduction in cost per square…