Related Posts

Couplings

Couplings With Blue Dog couplings, or connectors, you can ensure that the pressure flow is strong and stable throughout your abrasive blasting project. Coupling actually means the pairing of two

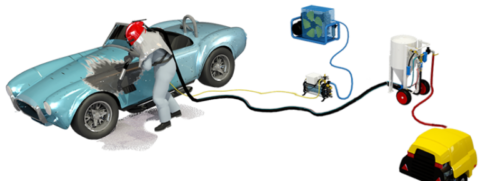

Why a Complete Breathing Air System Matters for Blasting Safety

Abrasive blasting environments demand a higher level of operator protection, and the breathing air system plays a central role in that safety equation. From airline filtration and climate control to…

Iron Grit Abrasive

Mohs Hardness: 7 Bulk Density: 160 lbs cuft Hard, Heavy good etching abrasive Breaks down in small angular pieces Wear on nozzles and hoses Angular Shaped / Dark Grey or…

Nozzle Comparison with Rust Removal

This test features the XL Performance Nozzle, Double Venturi Nozzle and the Long Venturi Nozzle. Each is being fed 90 PSI with an Empire 650 XL Sandblast Pot.

Abrasive Blast System Sizing Guide

Abrasive Blast System Sizing Guide With Blue Dog Blasting on your team, you have access to the sandblasting expertise that only comes with decades of sandblasting experience. The table below

Upgrading Your Blast Process as Your Powder Coating Business Grows

At Blue Dog Blasting, we typically see powder coaters upgrade their blasting process in three common stages: Good, Better, and Best. There are many ways to improve a blast operation,…