No products in the cart.

Blast Equipment Knowledge

Blast Equipment Knowledge

Home » Learning Center Old » Blast Equipment Knowledge

How Much Air Do You Need For Your Abrasive Blast Process?

Kevin Umphreyville

June 24, 2024

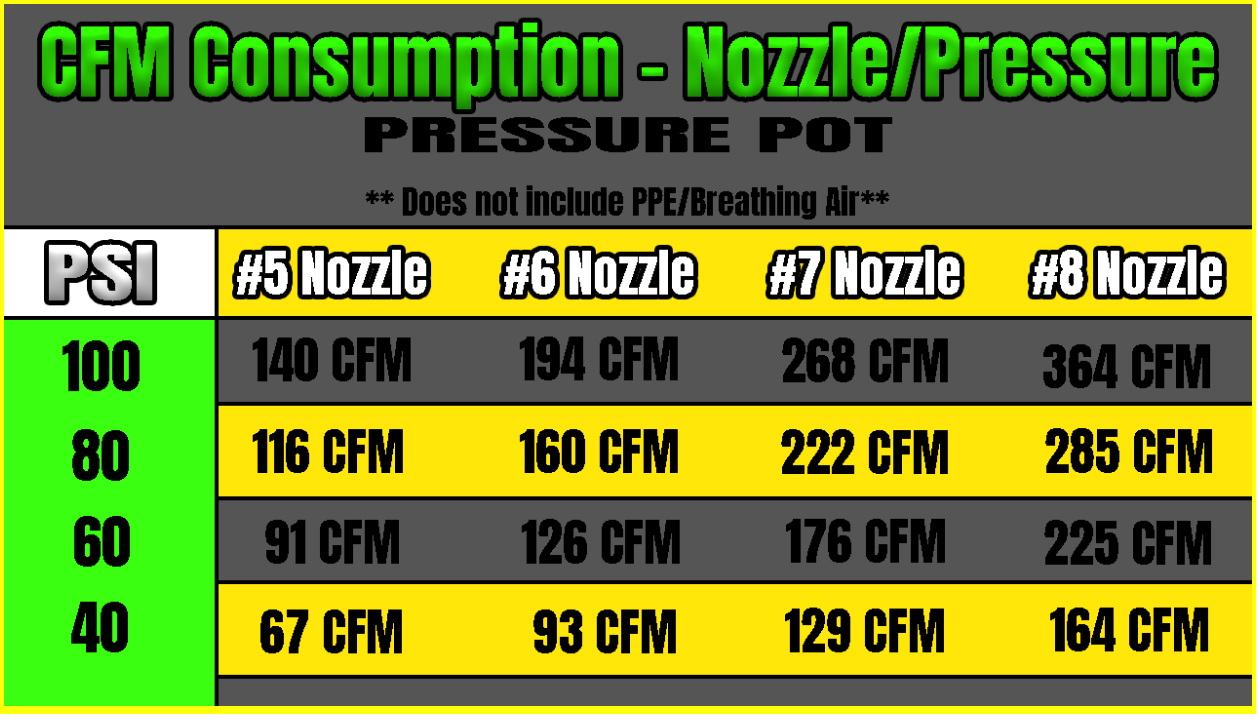

Return How Much Air Do You Need For Your Abrasive Blast Process? Abrasive Blast Process Air Consumption FAQs When it comes to air consumption for your abrasive blast process, how much is enough? How much compressed air do you really need for sandblasting? What are the correct blasting air requirements for your project? What size hose and nozzle is best for the size of your compressor and pot?This blog will answer those exact questions and ...

Learn More →

Double Venturi Nozzle

Ashton Principe

October 15, 2021

The tungsten carbide double venturi nozzle offers a 35% larger blast pattern than a standard long venturi. This is accomplished with only a slight loss in abrasive velocity. These nozzles are designed to be used on jobs where medium cutting action is required. They offer a more even dispersion of abrasive throughout the larger blast pattern. Excellent for plastic or agricultural abrasives. Also great when anodizing or powder coating.

Learn More →

Long Venturi Nozzle

Ashton Principe

October 14, 2021

The long venturi nozzle offers a 40% increase in production over a straight bore nozzle. Made with a protective polyurethane jacket, these nozzles are obviously built for physically demanding operations.

Learn More →

SiALON XL Long Venturi Nozzle – Rust Removal

Ashton Principe

October 14, 2021

This high-performance SiAION XL nozzle with Aluminum Jacket is made of a lightweight SiAION material that offers service life and durability similar to tungsten carbide at only half the weight. In other words, SiAlON is perfect for long jobs.

Learn More →

Nozzle Comparison with Rust Removal

Ashton Principe

October 14, 2021

This test features the XL Performance Nozzle, Double Venturi Nozzle and the Long Venturi Nozzle. Each is being fed 90 PSI with an Empire 650 XL Sandblast Pot.

Learn More →